Specialty equipment - design, manufacture, rebuild.

F C I has designed and/or built specialty drying and heat processing equipment in a number of counties for a wide range of products. Products processed include peanuts and other confections, peat moss, long fibre forages, pelleted forages, agri-pharmaceuticals, and a host of agricultural crops from beets to beans and carrots to canola. Energy sources include solar, electrical, natural gas, LPG, diesel/fuel oil, coal, wood/agri-fibre and ambient air. The total installed heating capacity that FCI staff have been involved with amounts to over 1,000 GJ/hr (1 Billion Btu/hr) in each of Canada, the U.S.A. and Australia, not to mention installations in several other countries.

Efficient and safe burners and control systems -

New and Upgrade Packages.

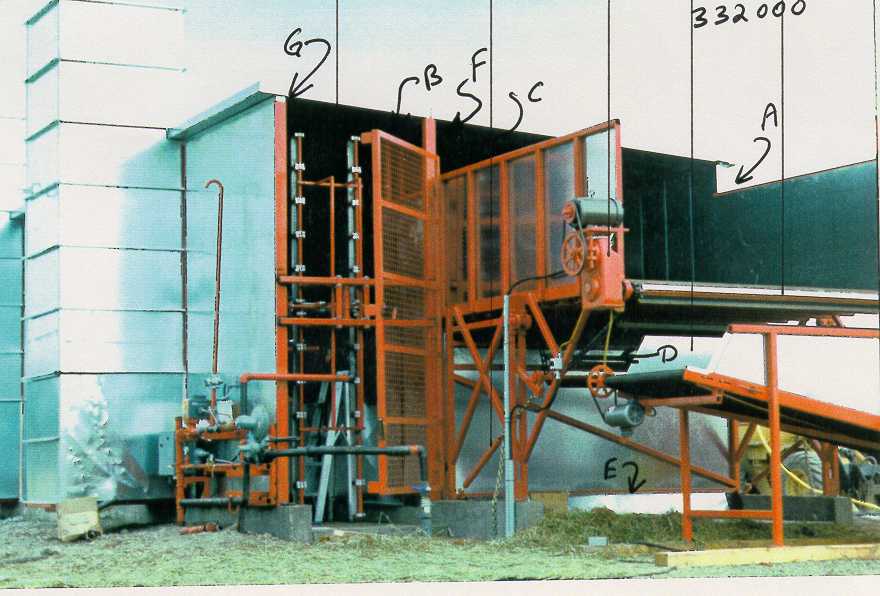

Just as the engine is the heart of most vehicles, the burners and fuel control systems are a key ingredient to a successful piece of equipment for heating, drying or processing. With the rising cost of fuel, effiecient burners and controls are critical. FCI staff have designed, rebuilt, manufactured, and/or installed a wide range of burners and control systems from 1 GJ/hr to the 50 GJ/hr (50 MBtu/hr) inputs. We are familiar with meeting/exceeding a variety of safety codes and standards, with many systems obtaining in-field approval under CSA B149.3. The picture at left is of a 50 GJ burner system for an alfalfa dehydrator, and below a 30 GJ burner control system for a long fibre hay processing installation,

Drum dryer burner/control upgrades.

FCI provides design/manufacture/refurbishing services, along with upgrades for burner/control systems, on a wide range of single pass and multiple pass drum dryers. Products range from peanuts to peatmoss, alfalfa to bulgor. Plant upgrades are a specialty.

Long fibre hay dehydration equipment - specialty design.

At left a long fibre hay drying facility prepares Timothy hay and other forages for export to Pacific Rim nations. A 30 MBtu/hr burner system provides abundant heat for drying and treatment. The processed forage feeds directly into balers (supplied by others) to double compress the product for economical shipping.

Confidential Design/ Fabrication.

Much of our work is conducted in confidence, with the resulting innovative processes and equipment forming part of the client's proprietary knowledge and business advantage. Although patent protection is sometimes pursued, for many clients the preferred alternative is to maintain exclusive knowledge of the innovation. Look at the pictures below for some of these confidential innovation projects --------- gotcha!

More to come.

Visit us again.